6.1Mould design capability

6.1.1Mayata is able to design the mould for hot forging and cold extrusion, especially for the bonding area of metal core and nylon, the strength ranges from 200~5400Nm.

6.1.2Mayata is able to design injection mould, it includes helical gear with direct injected teeth and overmoulded worm wheel blank. Furthermore CAE mould flow analysis is necessary to avoid any risks during injection process.

6.2Material developing capability

According to the manufacturing experience accumulated in the past years and the understanding to the resin material property, Mayata is able to choose appropriate material or develop new formula to meet product’s application. Main materials include:

A. PA66+GF25 for C-EPS worm gear.

B. PA66 for DP-EPS worm gear.

C. PEEK for engine balancer shaft.

D. POM for injected small gear.

6.3Lab test capability

6.3.1 Basic dimension inspection, it includes tooth accuracy grade, worm gear meshing accuracy grade, dimension inspection and dimension variation ratio inspection under different temperature and humidity conditions.

6.3.2 Performance test, it includes axial push-off test and interface static torsional test between the metal core and nylon, teeth static torsional strength test and endurance test.

6.3.3 Special test, it includes moisture content inspection, product cleanliness, melt index.

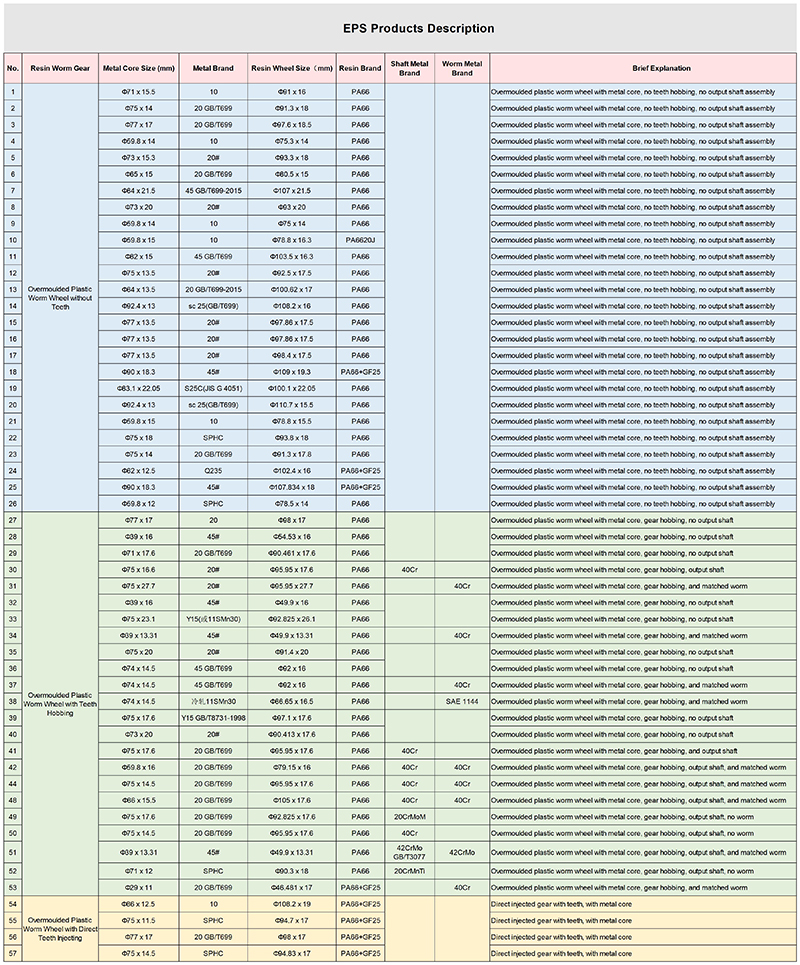

6.4Products application

A. Brushed C-EPS, SBW(steering by wire), EHB(electro-hydraulic brake, up to 45Nm.

B. Brushed and Brushless C-EPS of 45~65Nm

C. Brushless C-EPS of 65~90Nm

D. P/DP-EPS of 100~120Nm

E. ERCB for business vehicle above 130 Nm.

Name: Ms. Qiu Aiping

Mobile:13335781588

Tel:86-575-83050158 83050008

Email:mayata@mayata.com mayata@mayata.cn

Add:No.62, Zhenxi Road, Industrial Zone, Huangze Town, Shengzhou City, Zhejiang Province, China P.C.:312455