Zhejiang MAYATA Precision Machinery Co.Ltd. Started from the year of 2000. Mayata focus on the development and manufacturing of resin worm wheels and matched worms . Which are used in C-EPS (electric power steering),DP-EPS (electric power steering),SBW (steering by wire),EHB (electro-hydraulic brake system),and ERCB.

Meanwhile Mayata also engaged in developing and manufacturing not only thrust ball bearings, but also many kinds of high-performance & long service life special non-standard plane steering bearings, stainless steel thrust ball bearings, shield ball bearings for vehicles and plunger pump bearings for cleaning machines.

Our Motion--- Never-ending Science & Technology Creation and Innovation!

Our Mission---Green Production, Value Creation for Customers!

... Learn More

The Second Meeting of the 10th Council of the Steering Gear Branch of China Association of Automobile Manufacturers was Successfully Held in Shengzhou

The Second Meeting of the 10th Council of the Steering Gear Branch of China Association of Automobile Manufacturers was Successfully Held in ShengzhouDuring June 3th to June 5th 2025, The second meeting of the 10th council of the Steering Gear Branch (SGB) of the China Association of Automobile Manufacturers (CAAM) was successfully held in Shengzhou, Zhejiang, a city with beautiful view. The meeting was hosted by the chairman party, Hang Lung Group Ltd, and organized by Zhejiang MAYATA Precision Machinery Co., Ltd. The leaders of the CAAM an

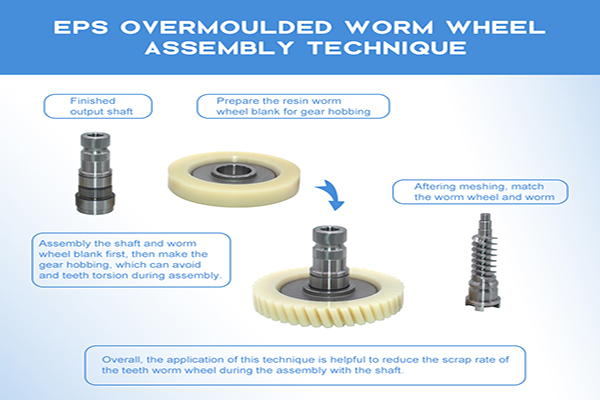

EPS overmoulded worm wheel assembly technique

EPS overmoulded worm wheel assembly techniqueOverall: The original assembly process is to assembly the teeth finished worm wheel with the output shaft. It will cause micro teeth torsion during the assembly process. Now assembly the worm wheel with the output shaft before teeth hobbing. It ensures the teeth accuracy, reduces the scrap rate.

EPS (Electric Power Steering) resin worm wheel

EPS (Electric Power Steering) resin worm wheelYielded from the experience of EPS worm wheel production, Mayata developed several nylon resin formulas, and applied on the products successfully. Meanwhile Mayata designed many kinds of steel core plates according to different demands of the whole worm. Especially the one-unit axle design with integrated forged shaft and core plate, it skipped the process of assembling the output shaft with the …

Stainless steel bearing

Stainless steel bearingMayata’s stainless steel bearings range from bore 3mm to 85mm, with outer diameter from 8mm to 110mm. Detailed type numbers are including SF3-8mm~SF10-18mm, and S51100~S51117, S51200~S51212, S51305~S51310. Besides, Mayata also helps to design and make stainless steel bearings of special purpose for not only food machinery and but also adjuster of railway brake system. We will choose appropriate

Introduction of automotive parts

Introduction of automotive partsWe design and develop a series of automotive products based on the experience accumulated in production technology and cooperation for material developing with Science and Development Institute, covering processes of forging, machining, heat treatment, grinding and plastic injection.